Edinburgh, Scotland – [November 20, 2024]

CSignum has partnered with Thordon Bearings to launch a new wireless propeller shaft bearing wear measurement system. This marks a significant advancement in propeller shaft condition monitoring, providing an efficient and more cost-effective approach to collect essential data for commercial and naval shipping.

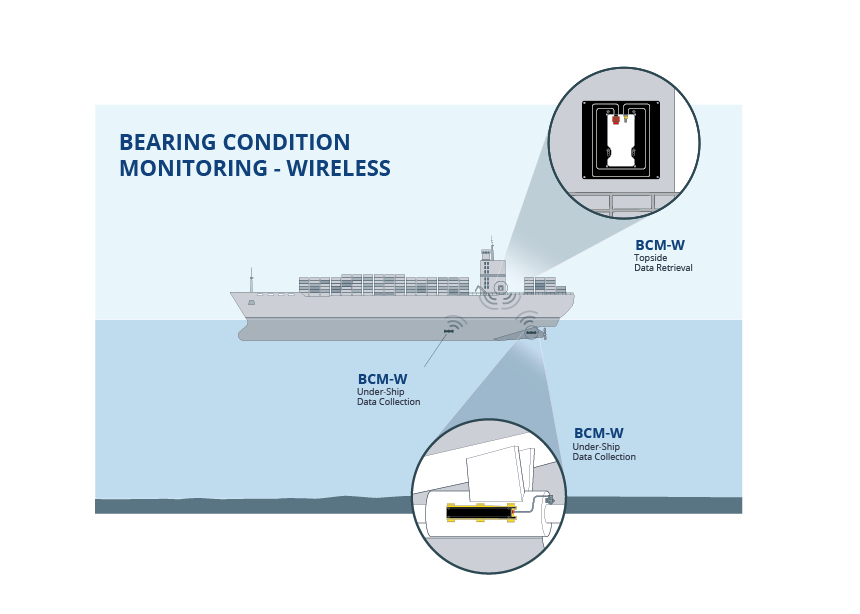

CSignum’s patented electromagnetic field signaling (EMFS) technology provides the means to transfer data from underwater sensors to monitors positioned above the waterline for Thordon’s Bearing Condition Monitoring – Wireless (BCM-W) system.

Jonathan Reeves, CEO of CSignum, said:

“This is a real game-changer for the maritime industry. The manual inspections which dominate today’s monitoring approaches cannot provide continuous, real-time data, making it challenging to promptly address emerging issues.

“CSignum’s EMFS wireless technology significantly improves monitoring by offering a cable-free solution that offers a way to monitor dynamic operating conditions, overcomes the limitations of traditional methods.

“We empower ship operators to address potential issues before they become major problems by enabling continuous, real-time data collection. This enhances operational efficiency and reducing the impact of operations on the environment.”

Thordon Bearings’ Technical Director Anthony Hamilton said:

“Typical wired bearing condition monitoring systems can be installed during the newbuild stage, but unlikely to be used in retrofit applications as the shaft needs to be withdrawn to install the cable.”

“Shaft withdrawal is not required with the BCM-W. It eliminates the need for cumbersome and penetrative cabling and removes the need for frequent and costly diver inspections. This level of reliable, on-demand information minimises ship downtime, helps keep vessels operational, and reduces maintenance costs.”

Simple to install afloat or in drydock, the BCM-W incorporates a non-intrusive sensor bolted on to the vessel’s sterntube and/or ‘A’ or ‘P’ bracket flange that is connected to the state-of-the-art subsea modem.

Bearing clearance information is then transmitted to a topside modem data retrieval unit sited on an upper deck bulkhead. It is from here that ship operators upload bearing clearance data to a tablet or laptop.

“With the Thordon BCM-W, ship operators can now easily log bearing wear rates and clearance trends,” said Hamilton. “Any sudden changes that indicate shaft misalignment can be quickly detected. Current wireless data transmission technology is unable to cross the water to air boundary.”

While the Thordon BCM-W has been developed for seawater-lubricated bearing clearance monitoring, the technology can be easily integrated with other sensors to provide a more holistic view of the ship’s hull below the water line. For example, the technology can be used to monitor other data from other sensors, besides the bearing clearance. For example, temperature, strain gauge, salinity, etc.

About CSignum

CSignum specializes in developing wireless communication solutions that transmit reliable data through challenging mediums such as water, ice, and soil. Focused on water quality, wastewater, and environmental monitoring, CSignum’s patented technology enables organisations to meet high regulatory standards while protecting vital water resources for future generations.